Metalens technology is revolutionizing the way we think about optics, offering unparalleled advantages over traditional lenses. Developed initially in the lab of Harvard’s esteemed Professor Federico Capasso, this innovative mini-lens device utilizes light-bending metasurfaces to achieve remarkable optical performance at a reduced size and cost. As Rob Devlin, CEO of Metalenz and a former doctoral student at Harvard, leads the charge in mass-producing these breakthrough components for consumer electronics, we witness an exciting shift in the industry. With over 100 million units already deployed in popular devices such as the iPad and Samsung Galaxy S23 Ultra, the potential of metalens technology is being realized in everyday products. This technological leap not only enhances user experiences but also opens new avenues for applications like 3D sensing and enhanced imaging capabilities.

The advent of metalens technology signifies a pivotal advancement in optical engineering, where traditional lens fabrication methods are being reimagined through the use of novel mini-lens innovations. Leveraging advanced metasurfaces, these sophisticated optical devices manipulate light with unprecedented precision, paving the way for new functionalities in various consumer electronics. Spearheaded by Rob Devlin’s startup Metalenz, these innovations have begun to reshape the landscape of lens design, integrating seamlessly into a multitude of applications. The unique polarization metasurface within this technology further enhances its versatility, allowing for security features and improved imaging capabilities. As the industry watches closely, this evolution in optics promises not only to disrupt established markets but also to create entirely new ones.

The Rise of Metalens Technology in Consumer Electronics

Metalens technology has emerged as a groundbreaking innovation in the realm of optics, particularly within the consumer electronics industry. By utilizing metasurfaces—thin layers engineered to control light at the nanoscale—metalenses offer a compact and cost-effective alternative to traditional glass lenses. This revolutionary approach allows manufacturers to produce lighter, more efficient devices, paving the way for advancements in smartphones, tablets, and cameras. Metalenz, the startup founded by Rob Devlin, exemplifies the successful commercialization of this technology, demonstrating the capacity for mass production and widespread market adoption.

The journey from academic research to real-world application for metalens technology highlights the intersection of science and entrepreneurship. Initially developed in the lab of Federico Capasso at Harvard, metalenses have seen quick integration into popular devices such as the iPad and the Samsung Galaxy S23 Ultra. This rapid progression illustrates the growing demand for innovative optics solutions that facilitate increasingly advanced features in consumer products. With millions of units produced and installed, the impact of metalens technology on the consumer electronics market is significant and poised to expand further.

How Mini-Lens Innovation is Transforming Optics

The mini-lens innovation, particularly through the development of metasurfaces, is set to revolutionize the optics industry by offering enhanced functionalities and design flexibility. Traditionally, optics relied on large, bulky lenses crafted from polished materials, which significantly limited the design possibilities for modern electronics. However, the introduction of mini-lenses allows for the integration of complex optical systems into smaller spaces, enabling manufacturers to create sleeker and more sophisticated devices. This shift not only enhances the aesthetic appeal of consumer products but also contributes to their overall performance.

Moreover, mini-lens innovation facilitates the incorporation of advanced features such as 3D sensing and augmented reality into consumer electronics. By optimizing space and cost, manufacturers can introduce novel functionalities that were previously unfeasible with conventional lenses. As Rob Devlin emphasizes, the ability to condense complex modules into smaller formats opens new avenues for device capabilities. This relentless pursuit of miniaturization and optimization signifies a crucial evolution in optics, influencing the future designs of consumer technology.

The Role of Metasurfaces in Advanced Imaging Solutions

Metasurfaces play a pivotal role in advancing imaging solutions, particularly in applications requiring precise depth perception and spatial recognition. By manipulating the properties of light, these innovative surfaces enable devices to capture more accurate 3D images, which are crucial for technologies such as facial recognition and augmented reality. The integration of metasurfaces into products like STMicroelectronics’ FlightSense module showcases their potential in enhancing functional imaging capabilities, significantly impacting consumer experiences.

As research and development continue to push the boundaries of metasurface technology, new imaging solutions will emerge across various sectors, from healthcare to environmental monitoring. For instance, the unique polarization signatures detected through polarization metasurfaces offer a groundbreaking approach to skin cancer detection by differentiating between healthy and unhealthy skin. This capability highlights the broader implications of metasurfaces in advancing diagnostic tools and enhancing the efficiency of existing imaging practices.

Metalenz: Bridging Research and Commercialization

Metalenz stands as a beacon of successful commercialization in the tech startup scene, effectively bridging the gap between academic research and market-ready products. Founded on the pioneering work of Rob Devlin and his colleagues at Harvard, the company epitomizes the translation of innovative ideas into commercially viable solutions. Their meteoric rise underscores the importance of collaboration between academia and industry, which fosters an environment conducive to groundbreaking advancements in technology.

As an example, Metalenz’s alignment with Harvard’s Office of Technology Development reflects the vital role that university partnerships play in nurturing startups. These relationships enhance access to intellectual resources and foster the exchange of ideas between disparate fields. By leveraging academic expertise alongside entrepreneurial spirit, Metalenz continues to stand at the forefront of optical innovation, signaling a promising trajectory for both the company and the future of optical technologies.

The Future of Optical Technology with Polarization Metasurfaces

The concept of polarization metasurfaces represents the next wave of innovation in optical technology. These advanced surfaces not only facilitate enhanced imaging and sensing but also introduce unique features for security applications in consumer electronics. For instance, by utilizing light polarization, Metalenz’s Polar ID system promises to provide smartphones with an additional security layer, potentially transforming the landscape of authentication methods in personal devices.

The reduction in size and cost associated with polarization metasurfaces allows for their implementation in a wider array of devices, democratizing access to advanced features traditionally reserved for high-end products. By making these technologies more accessible, Metalenz is paving the way for innovations that could redefine user interactions with devices. Further developments in polarization technology could lead to new applications, including environmental monitoring and medical diagnostics, showcasing the vast potential contained within these advanced materials.

Innovative Applications of Metalens Technology

The innovative applications of metalens technology extend beyond consumer electronics, offering exciting possibilities in various fields. With their ability to manipulate light at unprecedented scales, metalenses facilitate advancements in imaging, sensing, and even communication technologies. For instance, in the field of healthcare, metalenses may enable the creation of compact imaging devices that can provide accurate diagnostics while being portable and cost-effective.

Moreover, the integration of metasurfaces into various consumer products underscores their versatility across sectors. Applications in augmented reality, drone technology, and even automotive industries hint at the potential to revolutionize how devices perceive and interact with their environments. As research continues to progress, the adaptability of metalens technology hints at a future where sophisticated optical capabilities become an integral part of everyday gadgets.

Challenges and Opportunities in Metalens Manufacturing

Despite the promising advances in metalens technology, the manufacturing process presents both challenges and opportunities. One of the primary obstacles lies in scaling production to meet the growing industry demand while maintaining quality and precision. The ability to produce large quantities of mini-lenses with consistent performance requires sophisticated fabrication techniques and quality control measures, which can be costly and complex.

However, the challenges associated with manufacturing also open avenues for innovation and collaboration within the industry. Companies like Metalenz are exploring partnerships with semiconductor foundries to leverage existing manufacturing infrastructure, which could expedite production and reduce costs. In doing so, they will not only enhance their competitiveness but will also contribute to the larger push towards the democratization of advanced optical technologies in consumer electronics and beyond.

Metalenz’s Commitment to Ongoing Research and Development

Metalenz’s success and growth are closely tied to the company’s commitment to ongoing research and development. As emerging technologies evolve, the need for continuous innovation becomes paramount. By maintaining a strong relationship with academic institutions like Harvard, Metalenz ensures that it remains at the forefront of optical research. This partnership allows the company to tap into cutting-edge developments in metasurfaces, ensuring their products continually meet the demands of a rapidly changing consumer market.

Investing in research initiatives not only allows Metalenz to refine existing products but also aids in the development of new technologies that could redefine the industry. Rob Devlin’s vision to focus on innovation is critical in an age where technological adaptability can determine a company’s longevity. Continued investment in R&D will drive the next generation of optics, enabling Metalenz to sustain its competitive edge and lead the market in transformative optical solutions.

The Market Potential for Mini-Lens Solutions

The market potential for mini-lens solutions is vast, with increasing demand across various consumer electronics and emerging technologies. With products becoming more compact and multifaceted, the need for efficient optical systems has never been greater. Mini-lenses provide an opportunity for manufacturers to optimize space while introducing advanced features in smartphones, wearables, and smart home devices, ensuring they remain competitive in a rapidly evolving marketplace.

As companies like Metalenz capitalize on this market shift, their role in shaping the future of consumer technology becomes increasingly pronounced. As developments progress and new applications of metasurfaces are identified, the mini-lens industry is poised for exponential growth. This burgeoning sector not only promises to enhance the functionality of existing devices but also inspires a wave of innovation that could lead to entirely new product categories in the years to come.

Frequently Asked Questions

What is metalens technology and how does it differ from traditional lens systems?

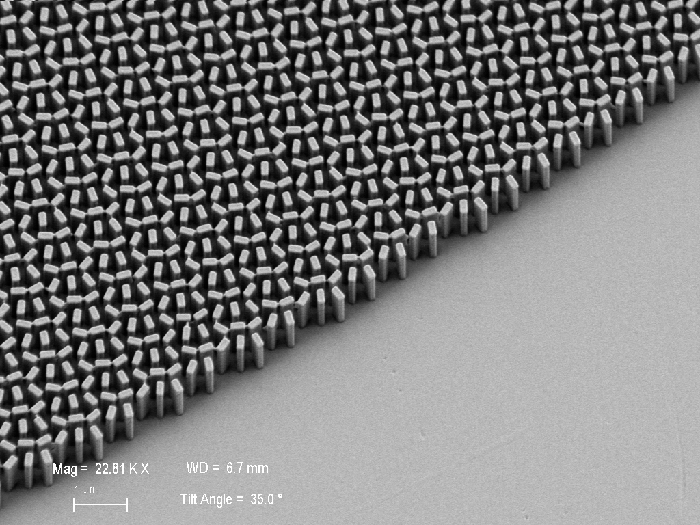

Metalens technology utilizes metasurfaces, which are ultra-thin materials composed of tiny pillars that manipulate light to focus images, unlike traditional lenses made from curved glass or plastic. This mini-lens innovation allows for reduced size and weight, making it ideal for compact devices in consumer electronics.

How are metalenses being used in consumer electronics today?

Metalenses produced by startups like Metalenz are currently integrated into various consumer electronics, such as smartphones and tablets. They enhance features like 3D sensing and facial recognition while taking up significantly less space than conventional lens systems.

What are the advantages of using polarization metasurfaces in devices?

Polarization metasurfaces, like those under development by the Rob Devlin startup Metalenz, offer advantages such as reduced size and cost for polarization cameras. They can provide unique polarization signatures for enhanced security in smartphones and even detect medical conditions through skin analysis.

How has Rob Devlin’s startup influenced the field of optics?

Rob Devlin’s startup, Metalenz, has transformed conventional optics by commercializing advanced mini-lens technology that leverages metasurfaces. This innovation not only simplifies manufacturing but also opens up new markets for smaller, multifunctional optical devices.

What is the role of metasurfaces in 3D imaging technologies?

Metasurfaces play a critical role in 3D imaging technologies by facilitating distance measurement with their specialized light manipulation capabilities. For instance, they are used in modules for applications like augmented reality and depth sensing, making them essential for modern consumer electronics.

How does MetaLens’s Polar ID technology enhance security features in devices?

Polar ID technology utilizes the unique polarization signature of individuals to enhance security in smartphones. This advanced feature allows for inexpensive and compact solutions compared to traditional polarization cameras, bolstering biometric authentication capabilities in gadgets.

What future applications can we expect from metalens technology?

Future applications of metalens technology include advanced medical diagnostics, environmental monitoring, and improved augmented reality experiences. As research progresses, innovations like enhanced hybrid systems combining different sensor capabilities are anticipated.

Why are semiconductor foundries important for the production of metalenses?

Semiconductor foundries are vital for the production of metalenses, as they enable mass manufacturing at scale, utilizing established fabrication techniques. This partnership allows startups like Metalenz to focus on development while leveraging the immense capacity of these foundries.

What challenges does the metalens industry face in terms of competition?

The metalens industry faces challenges from emerging competitors attempting to replicate or innovate similar technologies. Staying ahead requires continuous development and refinement of existing products and exploring new applications for metasurfaces to maintain a competitive edge.

How does Metalenz plan to expand its product offerings in the near future?

Metalenz aims to enhance its product offerings by developing new innovations that leverage their existing technology. Their ongoing relationship with academic researchers, like Federico Capasso, positions them to adopt the latest advancements in metasurface applications.

| Key Points | Description |

|---|---|

| Mini-lens Development | Rob Devlin developed an innovative mini-lens technology during his PhD at Harvard. |

| Company Creation | Metalenz was founded in 2016 to commercialize the metalens technology. |

| Mass Production | Over 100 million metasurfaces have been produced for consumer electronics. |

| Industry Disruption | Metalenz’s technology is transforming traditional lens-making, replacing bulky lenses with compact metasurfaces. |

| Major Clients | Devices utilizing Metalenz include products from Apple, Samsung, and Google. |

| Future Innovations | Development of Polar ID, a polarization metasurface for enhanced security at low cost. |

| Potential Applications | Applications include facial recognition, air quality monitoring, and medical diagnostics. |

Summary

Metalens technology represents a groundbreaking advancement in optics, shifting away from traditional lens-making methods. Developing mini-lenses in the Capasso lab has transformed the consumer tech landscape, enabling devices to become smaller, more effective, and cost-efficient. With Metalenz poised as a leader in this innovation, the future of optical technologies promises even more exciting applications, making essential contributions to industries including consumer electronics and medical diagnostics.